The bin filter is ideally suited for smaller quantities of chips and air or for extraction from finishing lines where the authorities demand a separate filter system. The bag filter takes up a minimum of room and can easily be installed along the building or in any position to the customer.

Datasheet

Our chain filters are designed to meet the needs of large high-volume dust extraction systems. Continuous cyclic filter bag cleaning is provided by insulated reverse flow regeneration fans to maintain the highest efficiency during all working conditions.

Our ATEX filters are equipped with specially designed explosion relief hatches on the hopper sides, which open quickly in the event of an explosion to maintain the structural integrity of the bag house. Channels mounted around the explosion relief hatches guide the flame discharges safely upward and away from the filter so that filter can be installed close to buildings etc.

The hatches are furthermore equipped with 2 spring- loaded re-closable latches and a microswitch. The filter has been explosion tested in full scale according to ATEX IEC 2014/35/EU and approved and certified Ex Dst 1, certificate NB 1026 FTZU.

Datasheet

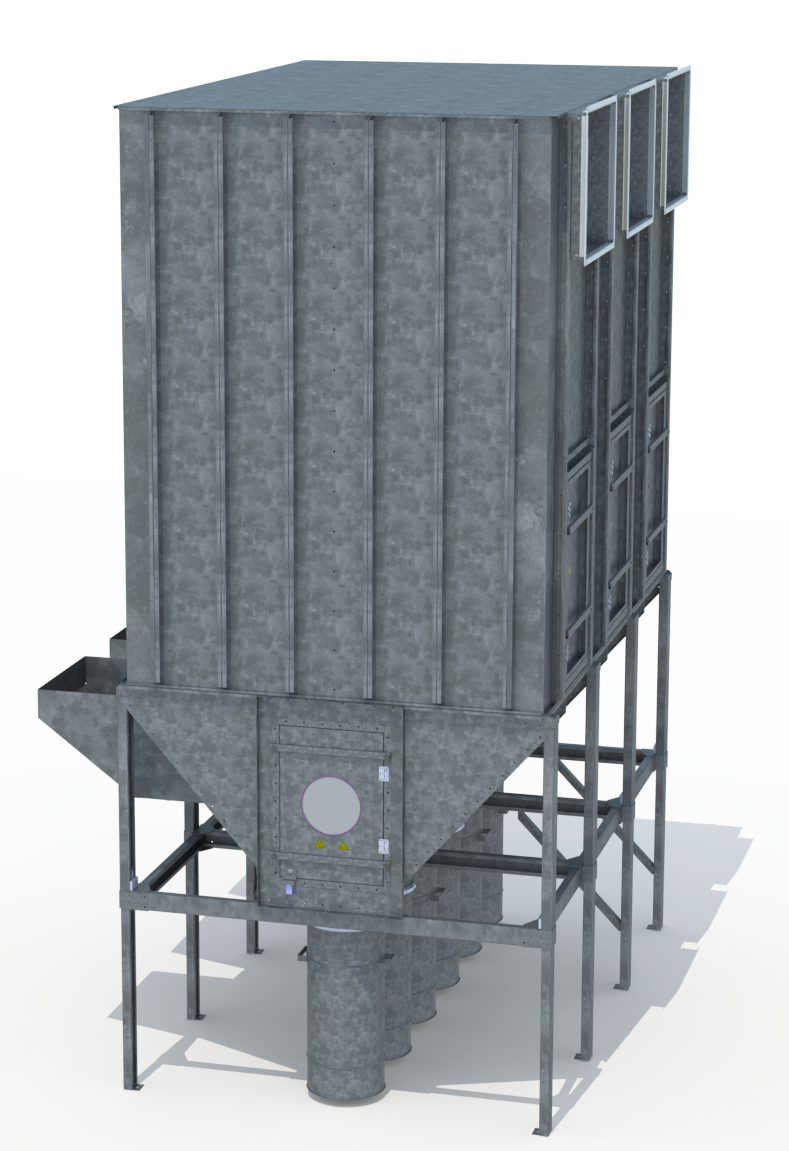

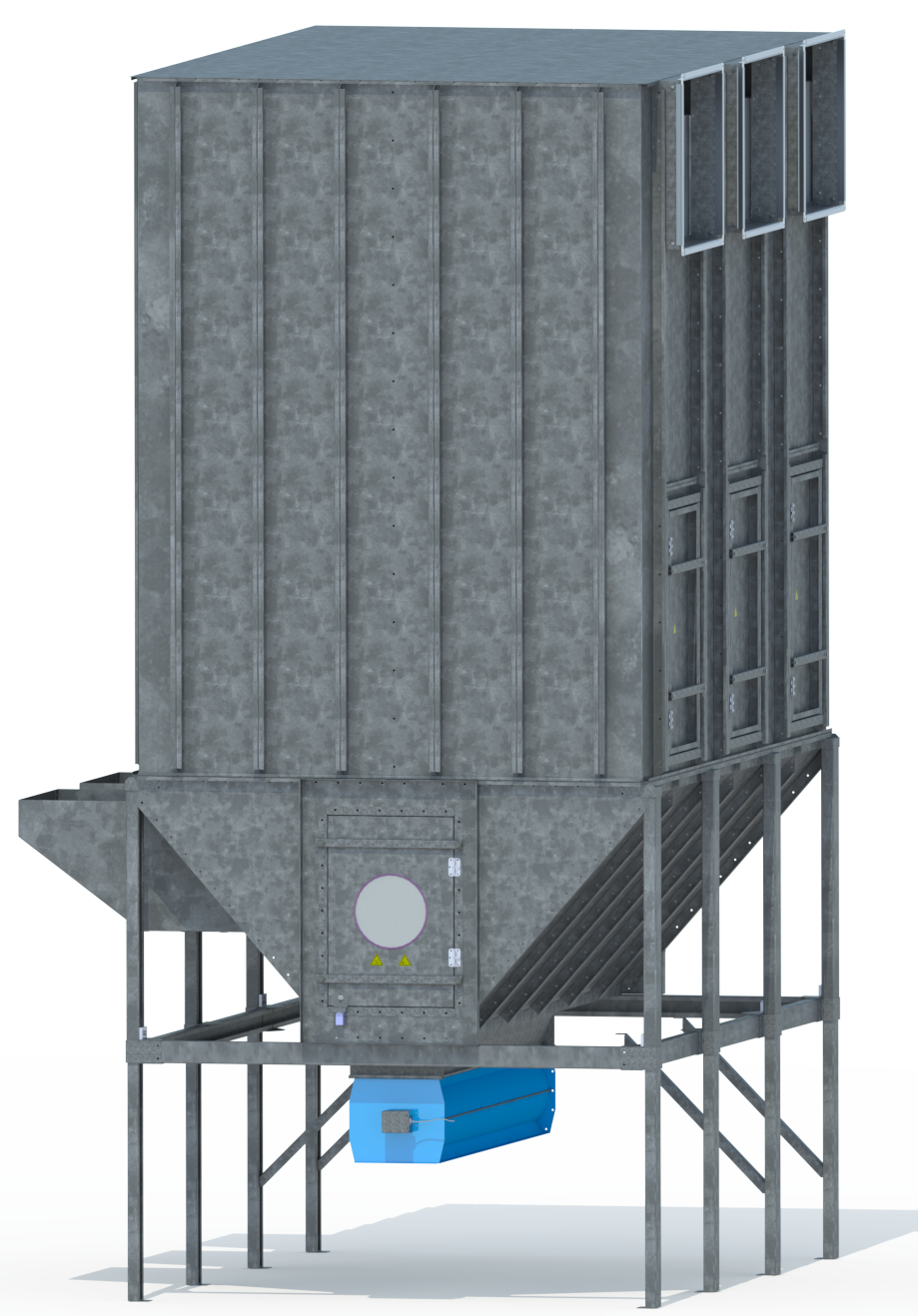

The rotary valve filter is ideally suited for medium-sized quantities of chips and air. The filter can also be fitted with a screw conveyor which is adapted to the special composition of chips.

Furthermore, the rotary valve filter can be designed to handle quantities of air up to approx. 25,000 m3/h. In case of larger quantities of air we would recommend a chain filter.

Datasheet

Get in contact with one of the members of the Aagaard UK team now: